What is composite material ?

DEFINITION

Composite materials also known as composite or composite materials, are composites made from two or more different materials that make up a new material that is more powerful than the original materials (When these materials work separately, turn).

Core ingredients

Mineral fiber group: Glass fiber, carbon fiber, ceramic fiber...

Group of thermally stable synthetic fibers: Kermel fiber, Kynol fiber, Apyeil fiber...

Other less common fiber groups: vegetable-based fibers (cellulose, woo...): paper, belt, hemp, pineapple, coconut... Mineral fibers: Asbestos fiber, silicon fiber...

Synthetic plastic fibers: Polyester fibers (Tergal, dacron, terylene...), polyamide...

Metal fibers: steel, copper, aluminum...

Composition

In general, each composite material consists of one or more discontinuous phases, distributed in a single continuous phase (phase is a component material in the structure of composite material), the continuous phase is called the material. Matrix is usually in charge of linking the discontinued phases. The discontinuous phase is called the reinforcement or reinforcement material mixed into the base phase to increase the mechanical properties, adhesion properties, wear resistance, scratch resistance...

Manufacture technology

- Contact mold technology:

+ Fingerprint

+ Spray

+ Paving machine

Mold technology with elastic diaphragm:

+ Vacuum mold

+ Autolave vacuum mold

+ Diaphragm mold

- Pressure impregnation technology:

+ Pressure impregnation in normal conditions

+ Pressure in vacuum

Die stamping technology:

Direct stamping

+ Casting

+ Hot pressing

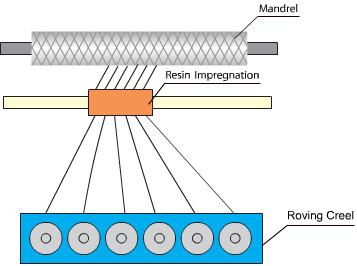

Wrapping technology:

+ Technology methods

+ Winding machine

- Pulltrusion technology

Advantages

The superiority of composite materials is the ability to fabricate this material into product structures according to the different technical requirements that we desire. The core components of the composite have high hardness, mechanical strength, and the base material always ensures the harmonious bonding of components to create structures that are heat resistant and resistant to corrosion of the internal materials extreme heat conditions of the environment.

One of the most effective applications is polymer composite, which has many advantages and is widely applicable with outstanding properties: Light, durable, environmental resistant, easy to install, has specific strength and elastic characteristics, is stable with corrosive chemical environments, low thermal and electrical conductivity. When fabricated at a certain temperature and pressure, it is easy to deploy technological techniques, convenient for the production process.

Composite classification

Composite materials are classified according to the shape and nature of the constituent materials:

Classification by shape:

+ Fiber-filled composite material: When the reinforcing material is fiber, we call it fiber-filler composite, fiber-filler enhances the mechanical properties of the substrate polymer

+ Granular-padded composite material: When the reinforcing material is granular, we call it granular-padded composite.

Classification according to the nature of ingredients:

+ Organic composite (plastic, grain) with reinforcement materials in the form: organic fiber, mineral fiber, metal fiber ...

+ Metal-based composite: Metal base with grain-type padding: Metal fiber, mineral fiber ...

+ Mineral-based composite with reinforcement materials in the form: metal fiber, metal beads, ceramic beads ...

Application:

Rocket engine case

Missile case, aircraft, spaceship

- Binh under high pressure.

3-layer high-grade composite petroleum pipeline (Using Russian wet sweep technology and standards for gasoline and oil pipe production).

Clean water pipes, raw water, composite source water (also known as fiberglass reinforced plastic pipes);

Wastewater and composite chemical conduits;

- Irrigation pipes, pipes for source water through salty water, alum contamination;

- Cover for tanks, cargo tanks, tables and chairs, interior decoration, composite panell panels;

- Garbage drainage system for high-rise buildings;

- The system of insulating porcelain, polymer porcelain, cilicon porcelain, epoxy porcelain of all kinds of chain porcelain, porcelain, delivery porcelain, porcelain in electrical equipment, lightning protection, fuse;

- Top cars, motorcycles, bicycles;

- Composite boat case (interest cover)...

- Public wastebasket.

- Model children's toys.

- Materials for home improvement.

For more information about this material, please contact Leeho Vina Co., Ltd for a complete and accurate way. With more than 40 years of experience in the composite materials industry, we believe that we will meet the most stringent requirements of our customers for product quality.

Thanks you so much!